IoT-Powered Vision-Enabled Quality Control System for a Packaged Food Company

Project Overview

A leading packaged food company faced significant challenges due to packaging defects, leading to product recalls, brand damage, and customer dissatisfaction. The company wanted a robust solution to automate its quality control process to ensure defect-free packaging and maintain high standards of product quality. iotasol developed an IoT-powered, vision-enabled quality control system using high-resolution imaging and Azure Machine Learning to detect packaging defects in real-time. This solution was designed to streamline the quality control process, reduce human error, and enhance overall operational efficiency.

Growth Tracking

75%

Reduction in Packaging Defects

50%

Decrease in Product Recalls

20%

Increase in Cost

Savings

Major Challenges

Packaging defects leading to product recalls and tarnishing the brand image.

Customer dissatisfaction due to defective packaging.

Solution

iotasol implemented an automated assembly line quality control system with the following key features

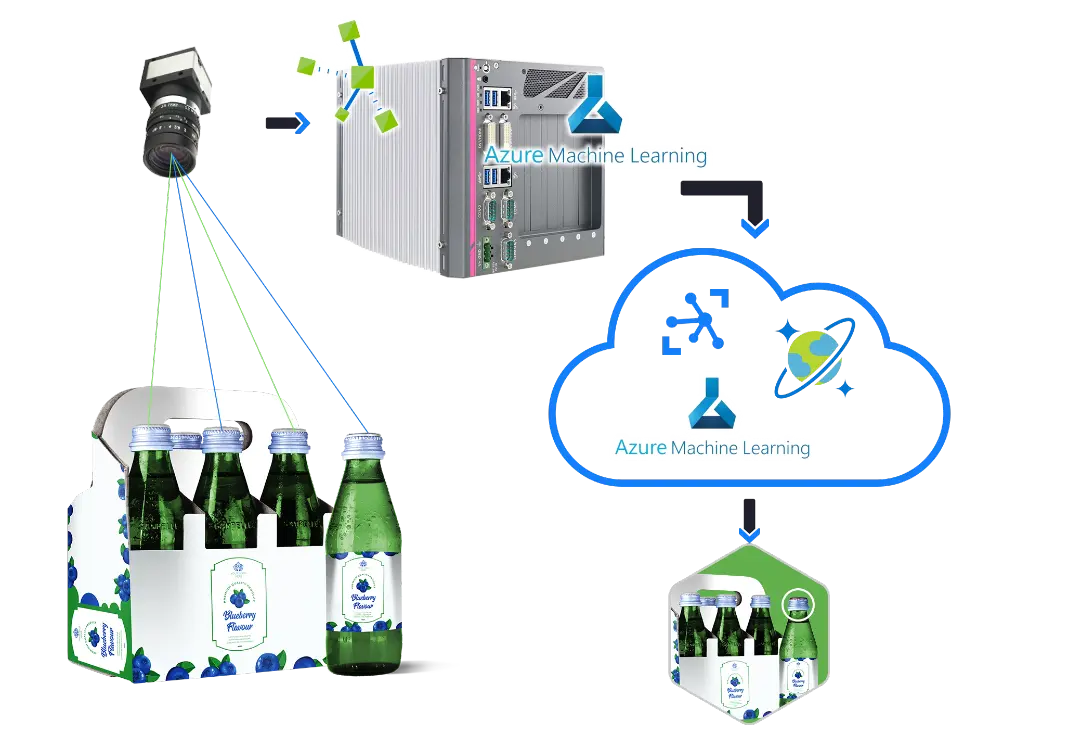

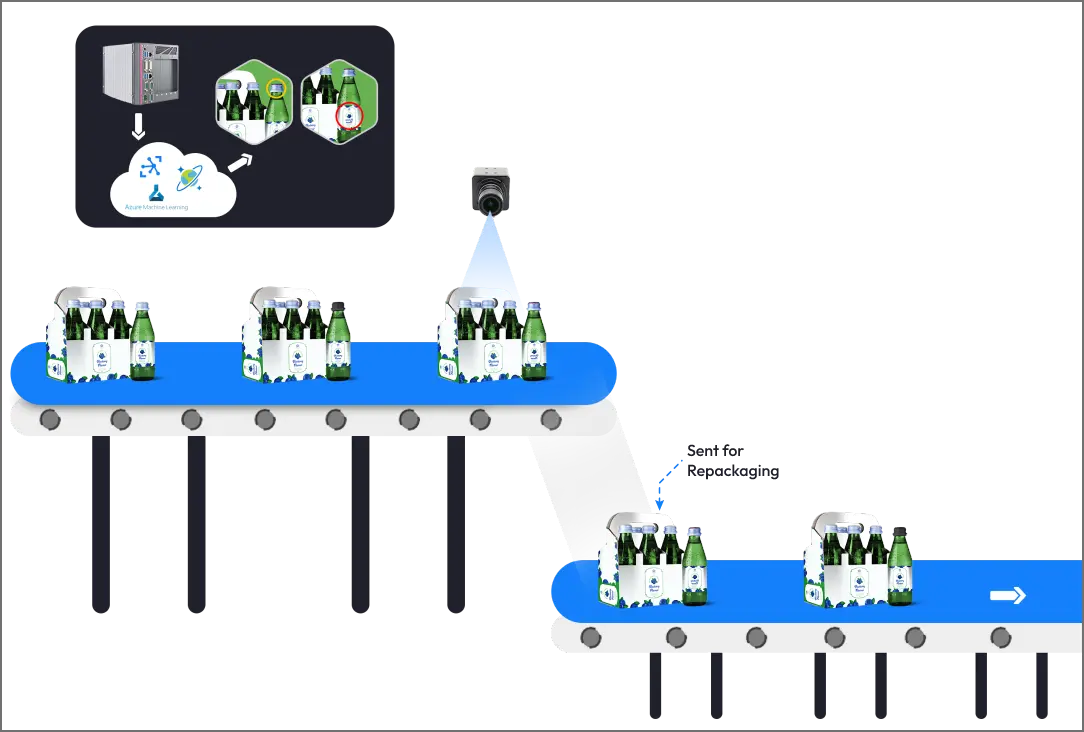

iotasol implemented an automated assembly line quality control system by integrating high-resolution cameras along the production line. These cameras captured detailed images of the top surface of food packaging before the final bagging stage. Utilizing Azure Machine Learning, the system analyzed these images to identify defects such as labeling issues and positioning errors. This technology enabled accurate and real-time detection of anomalies, ensuring that any defects were promptly addressed.

The solution was architected using IoT Edge and IoT Hub to facilitate seamless data collection, processing, and communication between devices and the cloud. Additionally, iotasol developed a cloud-based operational dashboard for real-time monitoring and reporting of the quality control process. This dashboard provided facility managers with comprehensive insights into defect patterns and overall operational performance, enabling data-driven decision-making and continuous improvement in quality control processes.

Outcome

Enhanced Quality Control: The automated system ensured consistent and accurate detection of packaging defects, reducing the likelihood of product recalls and maintaining brand integrity.

Increased Operational Efficiency: Automation of the quality control process reduced human error and streamlined operations, leading to improved productivity and reduced operational costs.

Real-Time Defect Detection: The use of high-resolution imaging and machine learning enabled real-time identification of defects, allowing for immediate corrective actions and minimizing defective products reaching the market.

Comprehensive Monitoring and Reporting: The cloud-based operational dashboard provided detailed insights into defect patterns and operational performance, enabling data-driven decision-making and continuous improvement.

Client Stories

Get in Touch for a live demo of IoT solutions over a workshop

Hear it From Our Clients

Taxtalk is a digital platform that provides premium tax accounting services to people and businesses across Australia. Hear Dominic Barba , CEO, Taxtalk speak about how iotasol helped them switch from a traditional business model to a technologically advanced and sustainable model

iBAG is an intelligent dry cleaning app that automates operations for service providers and simplifies customer experience. Aaron Pino, CEO of iBAG shares how iotasol, as their tech partner, crafted a versatile, futuristic app. He values iotasol's unwavering support and dedication

Listing Loop is a digital platform that allows early access to exclusive off-market properties across Australia. Hear it directly from the CEO of Listing Loop on what influenced his decision to entrust iotasol with all development work following some initial testing and how our work brought a significant impact on key business matrices

Carers Couch, connecting cancer caregivers with vital support, hails iotasol for their pivotal role. Martina Clark commends iotasol's trustworthiness and commitment, she says that iotasol goes beyond the role of a tech partner to ensure the vision behind a product is lived upto